In recent years, the use of laser marking machines has become an increasingly popular method for marking personal care products. With a growing demand for high-quality product labeling, laser marking machines have been praised for being a reliable, cost-effective, and environmentally friendly alternative to traditional inkjet printing.

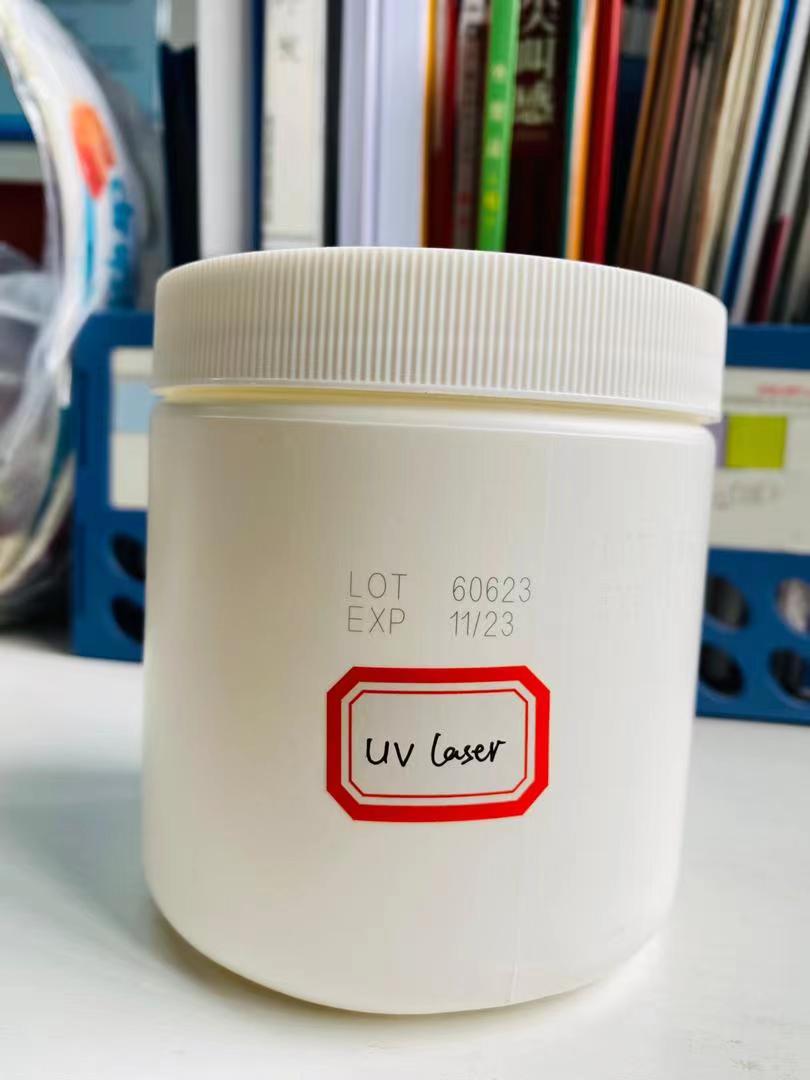

Laser marking machines utilize high-intensity beams of light to engrave information onto the surface of a product. Unlike inkjet printers, which use ink or other fluids to print images onto a product, laser marking machines use a laser beam to burn the surface of a product to create the desired markings.

One of the most significant advantages of laser marking machines over inkjet printers is their versatility. Laser marking machines can be used to mark a wide range of personal care products, including cosmetics, toiletries, and skincare products. They can also be used to mark a range of materials, including plastic, glass, and metal.

Another advantage of laser marking machines is their reliability. Unlike inkjet printers, which can be prone to damage, such as clogging or malfunctioning, laser marking machines are durable and require minimal maintenance. This makes them an ideal option for manufacturers who require high-volume production and demand consistent and reliable product labeling.

Furthermore, laser marking machines are a more environmentally friendly option than inkjet printers. Inks and fluids used in inkjet printers can contain harmful chemicals and solvents that can pollute the environment. Laser marking machines, on the other hand, do not use any such substances, making them a more sustainable alternative.

In conclusion, laser marking machines are a reliable, versatile, and environmentally friendly option for personal care product labeling. As the demand for high-quality labeling grows, laser marking machines are quickly becoming the preferred choice for manufacturers who seek to enhance product branding and improve customer experience.