Wire marking is an essential activity catered to by the ever-growing laser wire marking industry. But what is wire marking? Why has it become a need to mark our wires? How is it done and why is laser the most proper way to do it? If you are looking for answers to these questions, we wish to help you on your journey.

Today’s buildings are running all sorts of different equipment. Hospitals are running MRI machines and ventilators, factories are running manufacturing equipment and houses are running washing machines and televisions. To allow for these machines to operate, and in turn, we humans to function, we need wires and cables.

They help get the electricity in and send a signal in or out. With the immense amount of wiring in place, it can be a tedious task to organize them. Also, hooking the wrong wires can also have catastrophic effects. Consequently, wire marking is a simple yet effective method to overcome the troubles of the otherwise wiggly world of wiring.

In this article, you’ll get the useful guide about laser wire marking and major laser technologies, so you’ll learn how to improve laser wire marking.

Essentially, wire marking is labeling wires with information about them when one installs them. This important information helps us not only during installation but also when we work on or around the wires and cables in the future.

The activity of installing wires with labels and recording them accordingly, or planning before installation, may add up to additional work. However, it will save significant time and effort down the line.

It is like having a battle plan. You will be prepared to address any issues and take up any fights your wires may throw at you.

Why Is Wire Marking Needed?

Safety

To keep a facility up and running, there is a multitude of wires laid out. A vast majority of these are electrical wires, some of which are carrying high voltage currents. To handle them correctly is not a matter of choice as mishandling can have grave consequences.

With incorrect labeling, there is a high probability of accidentally cutting or unplugging the wrong wires, which can be hazardous. Incorrectly cutting a hot wire may lead to electrocution.

Similarly, a cut ground wire can result in a fire. A wiring setup with appropriate labeling can help address these issues or prevent the occurrence of hazardous scenarios.

Reliability

Wires are in use for electricity, data, and other things in a building and help keep devices and electronics running. There are instances, such as installation or removal of equipment, when unplugging or re-plugging of wires becomes necessary.

Unplugging the wrong wire can cause an outage of some type causing a machine to go down. This in turn will lead to reduced operation time and a drop in productivity. However, with correct wire marking, such a scenario is avoidable and this leads to increased reliability of all the systems in a facility.

Troubleshooting

For electronics and signals-based systems, faults often lead to troubleshooting of the wiring. For large and complex infrastructures, technicians might end up pulling their hair out while having to trace each wire.

Finding out which one could be causing the outage can take hours of extra time. Wires with proper markings will obviously alleviate this issue. It will allow maintenance staff to trace the fault easily and take corrective action.

Some Common Cables That Need Marking

Ribbon Electric Cables

Consisting of multiple parallel insulated wires, ribbon cables are in use for the transmission of multiple data simultaneously. For example, they can connect a hard drive to a motherboard and are also in use for the interconnection of networking devices.

Shielded Cables

It consists of 1 or 2 insulated wires which are covered by a woven braided shield or aluminium Mylar foil. The shielding permits better signal transmission and removal of irregularities in frequency and external interference. This is significant for signals such as those in radio.

Twisted Pair Cables

As the name suggests, this wire has two or more insulated copper wires which are twisted with each other and are color-coded. These types of wires are in use in telephone cabling.

Coaxial Cables

This cable is made using solid copper or copper-plated steel conductor by enclosing it in a metallic braid and metallic tape. This assembly is then put inside an insulation-providing protective outer jacket. These types of cables are used for computer networking and audio-video networking.

Fibre Optics Cable

There are these types of cables that transport optical data signals from a light source to the receiving device. Optical fiber is very common today and its uses are seen in a wide variety of applications.

Wire Marking vs. Conventional Marking

Conventional m. Laser etching machines arking and wire marking technologies do not differ significantly with regards to their core functionalityor inkjet printers will produce their output on the surface that needs marking. But it is not as simple when you consider a few practical factors.

For instance, the working surface for wires is small. This means the tracing technology that moves the laser head or an inkjet printer head across the surface has to have a lot more precision. Furthermore, the markings are being made on the insulation of a wire. Insulation coverings serve a very critical function of safety.

If these were to have any damage and reveal the actual conductor underneath, we have a recipe for disaster. From electric shock to short-circuiting, a myriad of things can go wrong. Hence the accuracy of the marking depth is very important.

With conventional marking, the tolerance limits are greater. Apart from depth, the marking technology for wires must have a high resolution. The data is marked as significant to the end-user. If it is not legible, the marking serves no purpose.

Wire Marking Market and Methods Available Today

On the basis of usage, the wire marking machine market can be broadly categorized into multiple industries. They include telecommunication systems, industrial wire marking systems, electrical systems, data communication infrastructures, and others.

From the technology perspective, the wire marking market can be categorized into inkjet, Hot foil stamping, embossing, and laser marking. The future holds significant growth in the pre-marked wiring segment.

As organizations look for a reduction in costs of equipment and supplies, this segment allows for maximum efficiency. Laser systems are leading the way in today’s world.

The telecommunication system segment accounts for a hefty market share. An increasing number of mobile phone and internet users across the globe is driving the demand sky high.

An increase in demand for an efficient telecom network, to reduce call drops and increase internet speed, is likely to keep the demand for network wires quite strong. The data communication market is likely to form the largest market share in the near future.

This is due to the increasing number of data centers across the globe. With the increase in the number of internet users, the amount of data they generate also increases. Consequently, data centers are expanding with time and hence need wiring to support their setups.

What Is Laser Wire Marking?

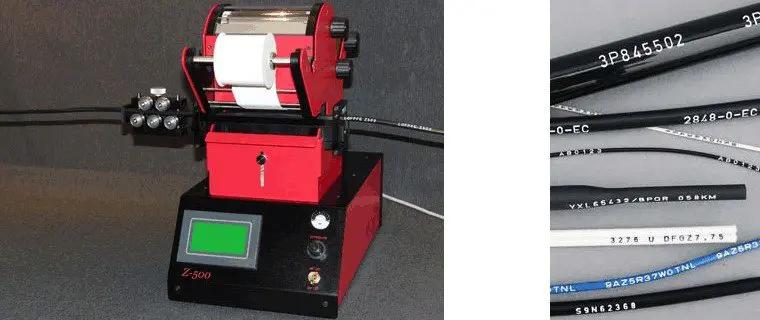

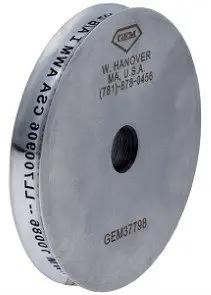

The laser wire marking machine permanently marks the insulation material that wraps around wires. A laser wire marker comprises a metal disc with cutouts. These are cutouts of all the letters, numbers, and symbols that one could need to make the marking.

The disc rotates to the appropriate position of the character in need and the laser light shines through it onto the wire in the shape of the cutout. The titanium oxide in the wire’s insulation material reacts with the laser light. This discolors the material and forms a permanent marking.

What Makes Laser Wire Marking Better?

Versatile And Less Damaging

Laser wire marking does not pose the risk of damaging the wires as other methods do. Hot stamping is the oldest way of marking wires that is still in use for some applications today. Hot stamping presses a hot mold coated with pigment into the wire’s insulation.

Since it marks by affecting the structural integrity of the insulation material, it has obvious detrimental effects. It can lead to breaking through the insulation down to the wire, making way for fluids or other contaminants to get in.

Also, laser wire marking allows for handling a wide variety of materials. For instance, hot stamping cannot effectively mark on materials like Teflon wiring whereas laser can.

Usage On Thinner Gauge Wiring

The equipment of today is more advance and has more electronics on board than ever. Aircraft are an apt example. For an aircraft’s avionics systems to work, manufacturers need more wiring. More wiring means more weight.

To address this issue, thinner gauge wires are in use to create complex Electrical Wiring Interconnect Systems (EWISs). These complex systems are reliable at getting the task done and reduce excessive weight. Laser wiring marks these thinner wires effectively as they do not damage the insulation itself.

High Operational Speed

As it is a manual process, hot stamping wires can be time-consuming. Furthermore, human input implies there are many things that can go wrong. Consequently, more quality assurance checks need to be in place to ensure wires with damage are not sent to customers or are not put to use. Laser wire marking, on the other hand, is quick, efficient, and carries far less risk of damaging the wire itself.

No Use Of Consumables

The shortcomings of hot stamp marking lead to the usage of inkjet marking. Inkjet marking is a process of printing the information onto the plastic insulation’s surface. However, inkjet is also not good at handling materials such as Teflon.

Furthermore, it has higher operational costs due to consumables such as ink. Laser wire marking, by contrast, uses no such materials as it is just the light from the laser changing the chemistry of the pre-existing material.

Higher Reliability

Inkjet and hot stamping methods have longer processes with more steps to execute the task. This means more chances that something can go wrong. This higher probability translates into a high number of mistakes.

A laser wire marker, by contrast, is highly accurate. With only a few steps in process execution, there is a lower chance of something going wrong.

Major Laser Technologies

UV Laser Marking

UV laser markings produce a high contrast marking that is non-abrasive. However, not all polymers are markable, and dark color materials are also not apt for usage with UV laser marking.

Furthermore, higher complexity in machine design implies a higher upfront cost. Also, UV lasers tend to have a shorter lifetime, in comparison to fiber lasers. Hence they are not the only option considering a cost-benefit analysis.

Fiber Laser Marking

Today, these fiber lasers are among the most advanced products on the market for their stability, longevity, and relatively lower cost. Continuing advances with regards to the materials that one can mark by fiber lasers including metals and polymers as well as the speed at which items one can mark are in the works, even today.

Fiber laser components cost less than other marking methods. Moreover, the laser source is also known to have a longer life. High-quality lasers can last ten years or longer. Their design makes them inherently stable and the markings they make are permanent in comparison to other methods.

As these machines require minimal maintenance, their operational costs are also significantly low. However, there are limitations such as the inability to mark all materials. A vast array of materials is catered to but there are a few that cannot be handled.

Operational since 1987, UV laser marking on wire and cable insulation is helping increase speed and safety. The initial purpose was to create permanent markings on wires and cables with thinner walls.

Today, it has become the global aerospace industry standard for applying permanent codes on wires and cables. So much so that many newer aerospace cable housing material manufacturers are optimizing their products for UV laser markings.

But legacy cables in older aircraft or cables used in other industries may not be easily marked by this method.

Despite coming into existence in the early 1960s, it wasn’t until 1985 when experimentation with doping fiber cores by uncommon elements that today’s modern lasers with fiber sources came to be.

Scientists and engineers determined that ytterbium-doped laser was the most efficient, cost-effective laser source for solid-state lasers with a variety of applications.

Other Technologies At Work

Ink-Jet

Like any technology, inkjet comes with both pros and cons. It is a non-contact method allowing it to be extremely versatile. Another aspect of its versatility is that it can work on a broad range of materials. They offer high speeds and have low initial costs.

However, they are more prone to maintenance requirements and cleaning. Furthermore, there are consumables involved, such as ink, solvent, and replacement hoses. This means the low upfront cost might be offset by consumables cost.

Thirdly, the markings are not as permanent as achievable through other methods. Similarly, there is a high probability of ink smudging during the initial application. Apart from direct printing, cable label printers are also available. The labels are then attached to the wires.

Hot (foil) Stamping

Hot stamping is one of the earliest marking methods still in use today. – Stamping is done by pressing a preheated stamp with characters onto the surface of the material using a color stamping foil.

With low set up costs and a decent permanence of marking, hot foil offers a basic method for marking. However, as a cable marker, they can be dangerous. When marking thin insulation coverings, this method can easily burn through and expose the conductor underneath. Furthermore, it offers very few applications.

For instance, marking a twisted cable cannot be done. The markings require manual updating, (replacing the stamp characters) and require frequent cleaning. All of this manual labor increases the chances of errors.

Embossing

When embossing, the marking characters lie above the plane of the material. In the case of marking wires, an embossing wheel provides a raised legend above the wire jacket. By ‘indenting’ the jacket around the print and leaving the print untouched, the emboss effect is achievable.

Embossing has a low setup cost and offers permanent markings. However, frequent cleaning and manual application processes hinder it from becoming the go-to method for wire marking.

Conclusion

Hopefully, this article helps its readers navigate the world of wire marking machines and understand how laser wire marking machines on sale today is the technology leading the industry.