The power battery is the core component of the new energy vehicle. The quality of the lithium battery directly determines the performance of the new energy vehicle. Therefore, it has extremely high precision requirements for its manufacturing process and production equipment. The production and manufacture of lithium batteries are connected by a series of processes. The production process is mainly divided into three parts: pole piece manufacturing, cell manufacturing and battery assembly.

As an advanced "light" manufacturing tool, laser technology plays an important role in the front, middle and rear processing of power battery production lines due to its high efficiency, precision, flexibility, reliability and stability, low welding material loss, high automation and high degree of safety. effect.

Laser lithium battery equipment: used for processing in the front, middle and rear sections, and is standard in the power battery production line.

Application:

Covering multiple processes of lithium batteries, laser cutting/laser welding/laser marking/laser cleaning, etc., help improve battery performance and production efficiency.

// Laser Welding

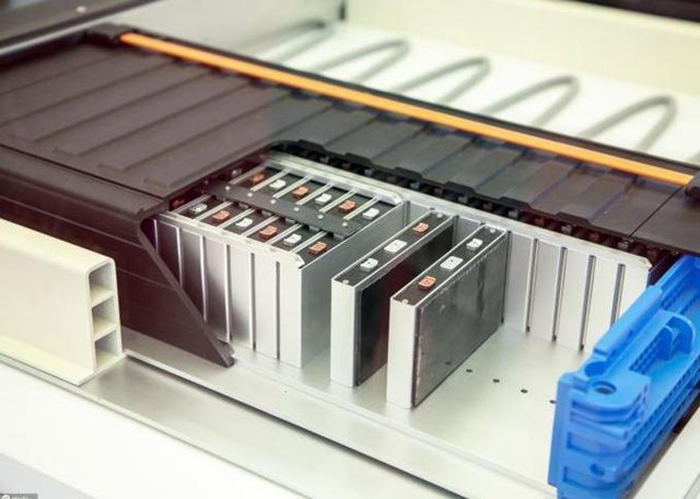

Laser welding is a process of using a laser beam to melt objects and realize welding. In the manufacturing process of lithium batteries and battery packs for new energy vehicles, there are more than 20 processes that need to be welded to achieve conductive connection or sealing.

Specifically, the laser welding application process includes:

(1) Pole piece production section - front section: The laser cutting process is applied to the pole piece and diaphragm slitting link.

(2) Cell assembly section - middle section: The laser welding process is applied to the welding links such as the shell, top cover, sealing nails, and tabs.

(3) Post-processing section - post-processing section: Welding of connecting pieces in battery pack module.

// Laser Cutting

Laser cutting is a process that uses a high power density laser beam to achieve cutting. Laser cutting has the advantages of no physical wear, flexible cutting shape, edge quality control, higher accuracy and lower operating costs, which is conducive to reducing manufacturing costs, improving production efficiency, and greatly shortening the die-cutting cycle of new products.

Specific application process of laser cutting:

In the production of power batteries, it is mainly used in the manufacturing of battery pole pieces in the previous process.

It includes laser tab cutting and forming of positive and negative electrodes, laser pole piece cutting, laser pole piece slitting, and laser cutting of diaphragms; among them, laser tab forming is currently the most important application of laser cutting in the field of lithium battery manufacturing.

// Laser Marking

In order to better control product quality and trace the entire production information of lithium batteries, it is necessary to store key information (including raw material information, production process and process, product batch, manufacturer and date, etc.) marked on.

The traditional ink jet coding technology has problems such as easy friction and easy loss of information for a long time, while laser marking has the characteristics of strong permanence, high anti-counterfeiting, high precision, strong wear resistance, safety and reliability, and can track product quality. Provide a good solution.

// Laser Cleaning

In the lithium battery manufacturing process, before welding the tabs, it is necessary to clean off the coating in the area of the tabs to be soldered. The methods of removing the coating mainly include mechanical scraping, styrofoam and laser cleaning.

Among them, the mechanical scraping method is easy to damage the pole piece, and it is difficult to ensure that the coating is removed cleanly; the styrofoam method has many processes, high production costs, and is not suitable for anode water-based slurry.

Laser cleaning has the advantages of green, high efficiency, good cleaning effect, and little damage to copper foil. .